EDEK/Universität Kassel - Foto: Nicolas Wefers

Mushrooms instead of concrete: innovative biomaterials enable sustainable construction

#SustainabilityWhen we talk about cutting CO2, we usually think of green electricity or transforming transport. However, a less obvious area – the building sector – offers huge potential for savings. A Kassel University researcher wants to combine biomaterials with digital manufacturing technologies and make them available for architecture.

When combatting climate change, we should not lose sight of one very important causal link: the construction industry. This sector alone accounts for almost 40% of global CO2 emissions. In view of the growing world population and the corresponding demand for living space, this figure is likely to rise even further – the construction sector, though, also offers huge potential for savings. "The level of digitalization in the construction industry is still quite low compared to other sectors," reports Philipp Eversmann, architect and professor at the University of Kassel, where he is head of the Department of Experimental and Digital Design and Construction. "The construction industry is virtually predestined to tap into enormous CO2 savings potential as a result of new technologies and manufacturing processes. However, this calls for a radical shift in building materials towards renewable resources and the transition to a circular economy."

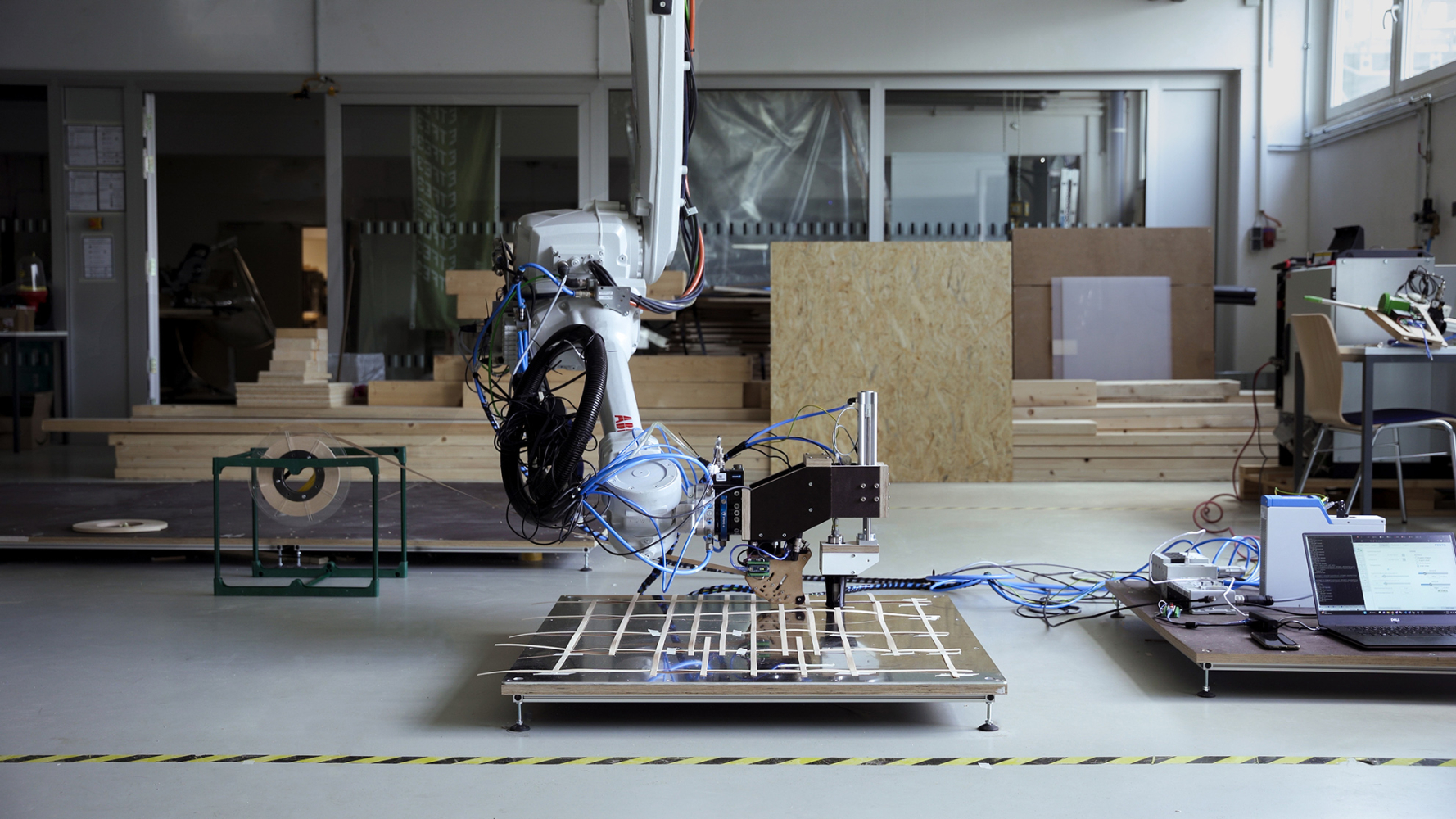

Eversmann has a clear vision of which new technologies could be the key to reducing greenhouse gases. His main focus is on digital design, robotic manufacturing techniques, and biomaterials that absorb CO2 during their growth process. However, anyone who thinks that wood might be the most suitable renewable raw material in this context would be very much mistaken. "I have been working with wood as a building material for many years. However, it takes decades for a tree to grow to the point where it can be used as a building material. That's why I asked myself whether other materials could be used that don’t take so long to grow, can be produced almost anywhere, and can be shaped into any form you want."

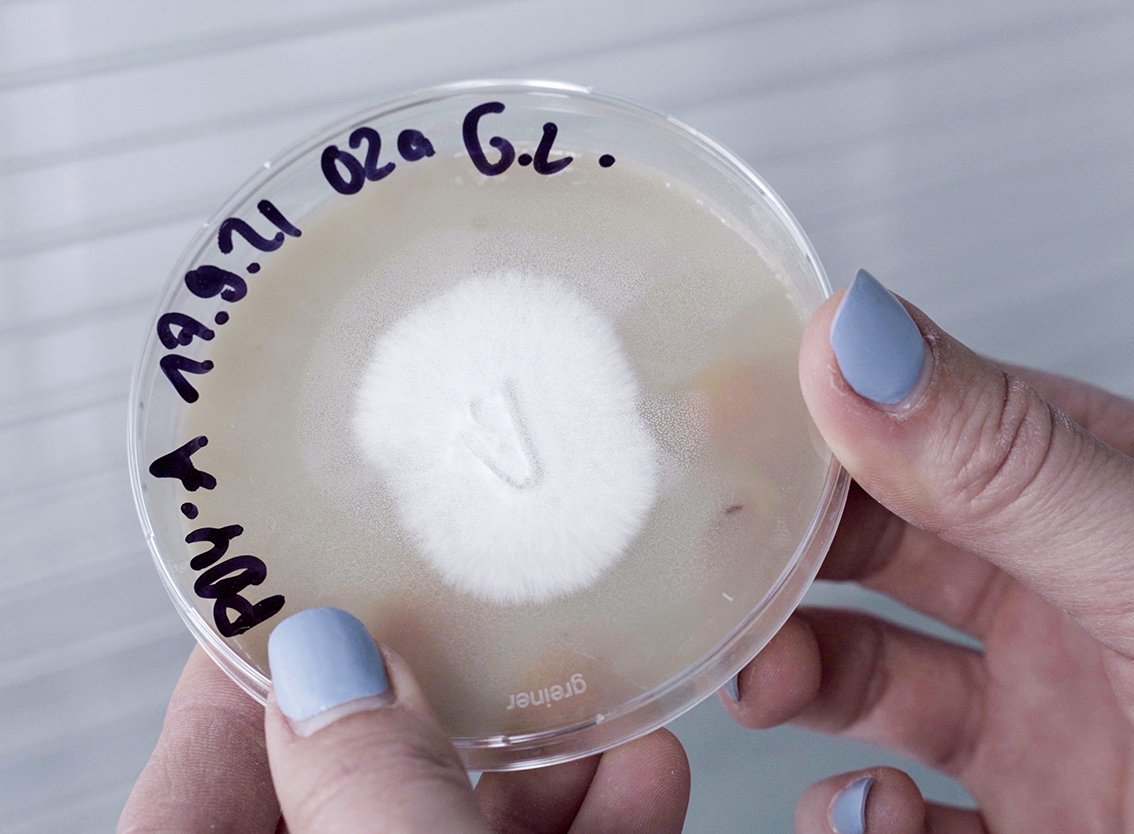

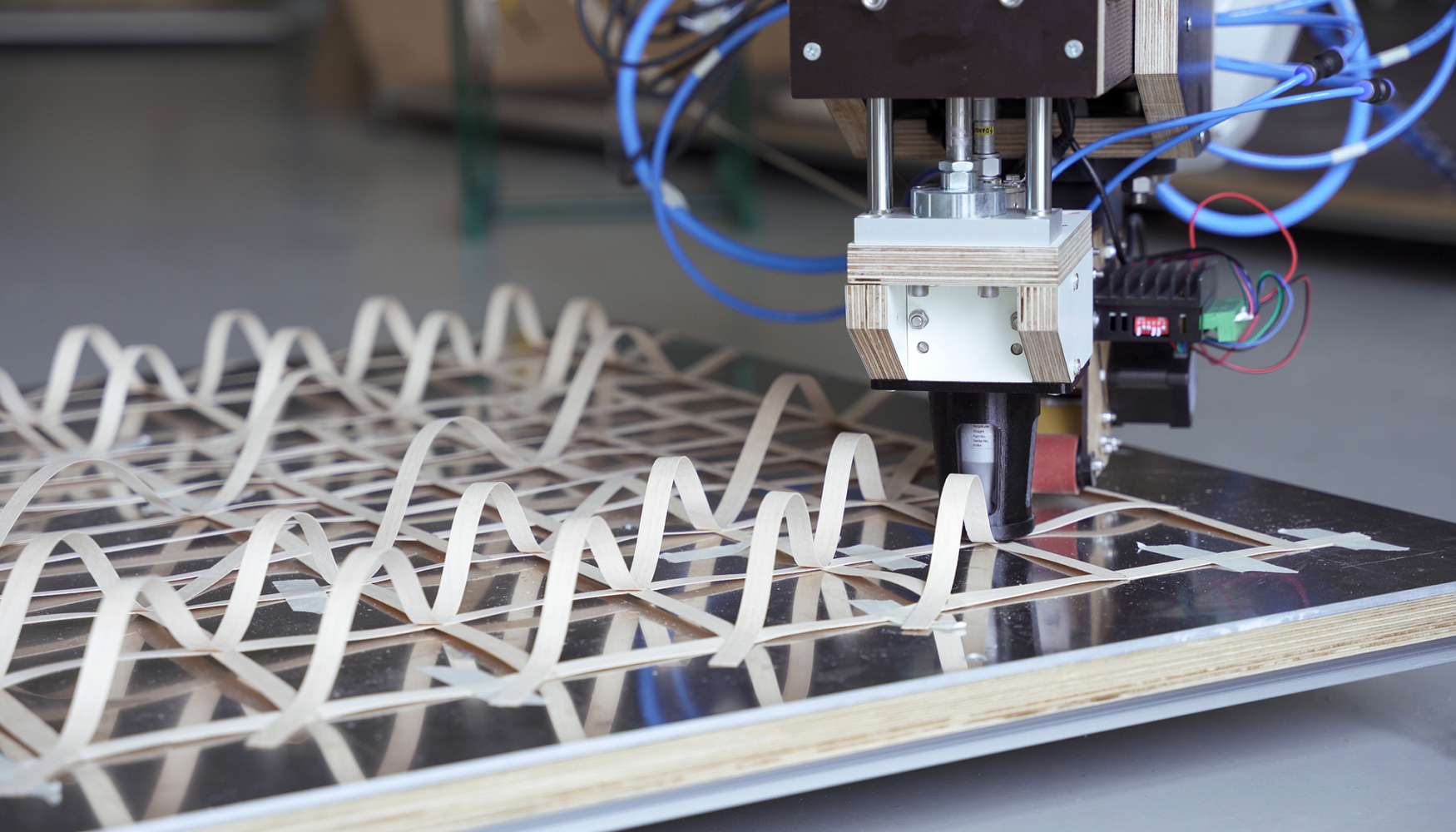

Alternative biomaterials open up completely new potential here. In contrast to conventional manufacturing techniques, their growth processes can also be integrated into the design and production process. This makes it possible to grow the material into certain shapes, adapt the material properties, or produce reinforced composite materials. Fungi are a good example of this. More precisely, their root network, the mycelium. Under laboratory conditions it is possible to precisely control and monitor the growth of mycelium. The growth process only takes a few weeks – and as the fungal mycelium grows on a spreadable substrate, there are virtually no limits to its shape. "This opens up completely new design possibilities," explains Eversmann, "but also requires a lot of knowledge that we first have to acquire."

First to the grassroots, then into practice

However, as research in the field of ecologically compatible materials is still mostly in its infancy, Philipp Eversmann wants to focus initially on basic research. He believes this is the only way to expand and further professionalize existing research in the field of sustainable construction. "For such an innovative and, of course, unusual research project, I needed a sponsor who would be willing to support me over the longer term," reports Eversmann. "The Volkswagen Foundation's Momentum Initiative offers exactly the right framework for this." Via this program, the Foundation supports scientists in an early phase after taking up their first tenured position, enabling them to explore opportunities to further develop the content and strategy of their professorship.

Eversmann has settled on a three-part research strategy. Firstly, he and his team want to test and optimize design and manufacturing processes with living materials under laboratory conditions. The focus here is on individual design options in terms of aesthetics, performance characteristics and source material (e. g. algae, microbes, etc. in addition to fungal mycelium). In a further step, he wants to concentrate on design and manufacturing processes using waste materials in order to create circular systems. To this end, he wants to use plant and agricultural waste, the remains of shellfish, and waste wood. In the third step, the researcher wants to investigate the bonding of materials. This is because the use of new types of materials requires new types of bio-bonding systems that can withstand structural, physical, and production-related requirements such as bio-welding or form-fit joining.

High-tech for scalability

"We have to break through technological barriers because biofabrication processes have unique technical requirements," explains Philipp Eversmann. For his three sub-projects, he wants to develop a new robotic biofabrication infrastructure at his chair. In addition to acquiring biolab equipment such as a cleanroom area and a growth chamber, he plans to develop modular software and hardware for design and production, for example to predict and specifically program material behavior using simulations and machine learning.

"The requirements for sustainable architectural applications are much more demanding, as the entire life cycle must be considered, and biomaterials are subject to a natural regeneration process. In our research laboratories, we investigate this on various scales up to 1:1 prototypes and establish contact with industry at an early stage in order to create scalability for large applications." Eversmann wants to make the results of his research available to other researchers in the form of publications, databases, open-source tools, and software projects. The aim is to increase the number of theories, applications, innovators, and experiments over the long term in order to advance methods for sustainable digital manufacturing in the field. "We want to make sustainable biomaterials available to practice as quickly as possible wherever alternative building materials are urgently needed," summarizes Eversmann.

The Head of the Department of Experimental and Digital Design and Construction, Prof Philipp Eversmann.